User Tools

Sidebar

projects:3dprinter

Book Creator

Add this page to your book

Add this page to your book

Book Creator

Remove this page from your book

Remove this page from your book

Table of Contents

3D printer

Resources

-

- mount heatbreak and nozzle touching toghether and with 0.5mm gap between head and nozzle

- preheat hotend at ABS temp

- fix nozzle with 1nm torque

-

- set combing mode to off

z offset: subtract 0.25 to A4 paper without friction and without warm up

Printing tips

- Initial Layer Speed: 20mm/s

- Combing mode: not in skin

- Maximum Comb Distance with No Retract: 10mm

- Initial Layer Line Width: 140%

PLA:

- z-hop: 0

PETG:

- first layer: 245

- other layer: 245

- bed: 80

- z-hop: 0.6

- cooling: 50%

ABS:

- first layer: 250

- other layer: 240

- bed: 100

- z-hop: 0.6 or 0

- adhesion: brim

- speed:

- 30mm/s for stronger material

- 50mm/s for weaker material

Anycubic 4max pro 2

- anycubic_4max_4maxpro2.0_petg_fast

[general] version = 4 name = 4MAXpro2.0 PETG fast definition = anycubic_4max [metadata] type = quality_changes quality_type = normal intent_category = default position = 0 setting_version = 19 [values] cool_fan_enabled = True cool_fan_speed = 50 infill_pattern = grid infill_sparse_density = 20 initial_layer_line_width_factor = 140 material_initial_print_temperature = =max(-273.15, material_print_temperature - 10) material_print_temperature = 245 material_print_temperature_layer_0 = 245 optimize_wall_printing_order = True raft_margin = 5 retraction_combing_max_distance = 10 retraction_hop = 0.6 retraction_hop_enabled = True speed_layer_0 = 20 speed_print = 50 speed_print_layer_0 = =speed_layer_0 speed_travel = 100 speed_travel_layer_0 = =speed_layer_0 * speed_travel / speed_print top_layers = =0 if infill_sparse_density == 100 else math.ceil(round(top_thickness / resolveOrValue('layer_height'), 4)) travel_avoid_other_parts = False wall_line_count = =1 if magic_spiralize else max(1, round((wall_thickness - wall_line_width_0) / wall_line_width_x) + 1) if wall_thickness != 0 else 0

- anycubic_4max_extruder_0_#2_4maxpro2.0_petg_fast

[general] version = 4 name = 4MAXpro2.0 PETG fast definition = anycubic_4max [metadata] type = quality_changes quality_type = normal setting_version = 19 [values] adaptive_layer_height_enabled = False adhesion_type = skirt default_material_bed_temperature = 60 layer_height = 0.3 material_bed_temperature = 80 material_bed_temperature_layer_0 = 80 retraction_combing = noskin support_enable = False support_type = buildplate

Flsun Super Racer

todo

Ender3 v2

- bed 70

- head 225

- Retraction Distance: 6.5mm.

- Retraction Speed: 25mm/s.

- Maximum Retraction Count: 10.

- Minimum Extrusion Distance Window: 10mm.

- Combing Mode: ON and set to “Within Infill” (no stringing).

- fan 100% for details or fan 0% for stranght

Geeetech A20

first layer speed 10mm/s

into start g-code keep only first G28 as below

G28; auto home G1 Z15 F300; linear move, 15mm vertical and set feedrate at 300 M107; turn fan off G90 ; absolute positioning M82 ; This command is used to override G91 and put the E axis into absolute mode independent of the other axes. G92 E0; set absolute position M107 ; M107; turn fan off G0 X10 Y20 F6000 ; move to X 10 mm Y 20 mm , feed rate 6000 G1 Z0.8 ; move Z to 0.8 mm [WHY MOVE VERTICALLY?] G1 F300 X200 E40 ; push 40 mm of filament while moving at 300 mm/min to position X=200 G1 F1200 Z2 ; move to position Z=2 at 1200 mm/min G92 E0 ; set the extruder position as the new zeros

fetch marlin code and checkout same branch release on Marlin.git and Configurations.git

apply this patch

git clone https://github.com/MarlinFirmware/Marlin.git #git clone https://github.com/Jyers/Marlin.git cd Marlin check out latest release branch, for example 2.0.9.2 git clone https://github.com/MarlinFirmware/Configurations.git cd Configurations check out latest release branch, for example 2.0.9.2 #git clone https://github.com/Jyers/Configurations.git # copy Configuration.h and Configuration_adv.h from examples cd .. rsync -av Configurations/config/examples/Geeetech/A20/ Marlin/ code . // select default shell to bash Terminal: Select Default Profile // change MOTHERBOARD #define MOTHERBOARD BOARD_GT2560_V4_A20 // enable bltouch if present // comment PROBE_MANUALLY and decomment BLTOUCH //#define PROBE_MANUALLY #define BLTOUCH #define Z_MIN_ENDSTOP_INVERTING false // Set to true to invert the logic of the endstop. #define Z_MIN_PROBE_ENDSTOP_INVERTING false // Set to true to invert the logic of the probe. #define Z_SAFE_HOMING // temporary #define X_BED_SIZE 200 #define Y_BED_SIZE 200 #define X_MIN_POS -10 // original plate 260x260 //#define X_BED_SIZE 255 //#define Y_BED_SIZE 255 //#define Y_MIN_POS -5

install marlin auto build extension

change vscode settings.json

- javascript

{ "terminal.integrated.defaultProfile.linux": "bash" }

To upload firmware add a custom FFF (no geeetech A20 model) printer and use upload firmware menu

Anycubic Predator

-

- rename predatorimage.png.stl to predatorimage.png

custom spare parts:

Marlin firmware predator

clone this repository

clone this marlin 2.0.9

or update scipio

- download

cd /lab/printer3d/marlin-predator # only one time #git remote add upstream https://github.com/MarlinFirmware/Marlin.git git fetch upstream git rebase upstream/2.0.x

add to Marlin/Configuration.h

#define LCD_SCREEN_ROT_180

change

#define TEMP_SENSOR_0 11

decomment in Marlin/Configurationadv.h

<code>

Enable for M105 to include ADC values read from temperature sensors.

#define SHOWTEMPADC_VALUES

</code>

build project: in platformio select trigorilla-pro

<code>

scp .pio/build/trigorilla_pro/firmware.bin root@octoprint.local:/root

</code>

remove jumper jp1 and change other jumper to USB video

getting info

<code>

stm32flash /dev/ttyUSB0

stm32flash 0.5

http://stm32flash.sourceforge.net/

Interface serial_posix: 57600 8E1

Version : 0x22

Option 1 : 0x00

Option 2 : 0x00

Device ID : 0x0414 (STM32F10xxx High-density)

- RAM : 64KiB (512b reserved by bootloader)

- Flash : 512KiB (size first sector: 2×2048)

- Option RAM : 16b

- System RAM : 2KiB

</code>

make backup

<code>

stm32flash -r predator-original.bin /dev/ttyUSB0

</code>

write firmware

<code>

stm32flash -v -R -b 57600 -g 0x8000000 -w firmware.bin /dev/ttyUSB0

</code>

platformio.ini

<code>

[env:trigorillapro]

platform = ststm32

board = genericSTM32F103ZE

buildflags = !python Marlin/src/HAL/STM32F1/build_flags.py

</code>

=== Auto calibration ===

* configuration → delta calibration → auto → enter → wait → enter

* configuration → store

=== z offset ===

Disable software endstops (M211 S0), preheat and with motion z to grab paper: get deltaz (positive or negative, for example 0.3)

* configuration → runout sensors → off

* temperature → preheat PLA → preheat PLA

* motion → z

adjust probe z-offest adding deltaz:

* configuration → probe z-offest → =z-offest+deltaz

enable software endstops (M211 S1)

store settings

=== z babysteps ===

<code>

M290 Z0.25 ; move up 0.25mm on the Z axis

…

M500 ; store

</code>

==== PID autotune ====

start pid autotune at 220C and 8 cycles

<code>

M303 S220 C8

</code>

wait and

store proposed values with M301

<code>

M301 P13.83 I0.76 D63.18

</code>

save settings

<code>

M500

</code>

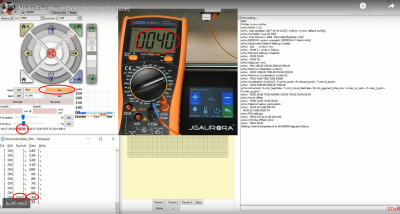

==== Thermocouple tuning ====

Get actual extrusor thermocouple from Menu → About → Thermistors and from Configuration.h get actual thermistor_xx.h utilized

set hotend to 200C from control and check in terminal ADC value (138.06 in example)

<code>

Recv: T:200.47 /200.00 (138.06) B:21.64 /0.00 (982.37) @:47 B@:0

</code>

projects/3dprinter.txt · Last modified: by scipio